Introduction

Embroidery machines are specialized equipment designed to create intricate and detailed designs on fabric or other materials. They use computer-controlled stitching mechanisms to create complex patterns and designs, making it easier for individuals and businesses to produce high-quality and customized embroidery.

Proper cleaning and maintenance of embroidery machines is crucial to ensure their smooth and efficient operation. Regular cleaning helps to prevent dust, dirt, and lint from accumulating inside the machine, which can cause it to malfunction or produce subpar embroidery results. Maintenance, on the other hand, involves routine inspections and repairs to address any issues or wear and tear that may occur over time.

By taking good care of their embroidery machines, users can prolong their lifespan, reduce the risk of breakdowns, and achieve better embroidery results. It is recommended that users refer to their machine’s user manual or consult a professional technician for guidance on proper cleaning and maintenance procedures.

Cleaning your Embroidery Machine

To ensure that your embroidery machine continues to operate smoothly and produce high-quality embroidery designs, it’s important to clean it regularly. Here are the steps you can follow to clean your embroidery machine:

Gather Necessary Materials

Before you start cleaning your embroidery machine, you’ll need to gather the necessary materials. This includes:

Soft lint-free cloth or microfiber cloth

Soft-bristled brush

Isopropyl alcohol

Sewing machine oil

Cleaning the Exterior of the Machine

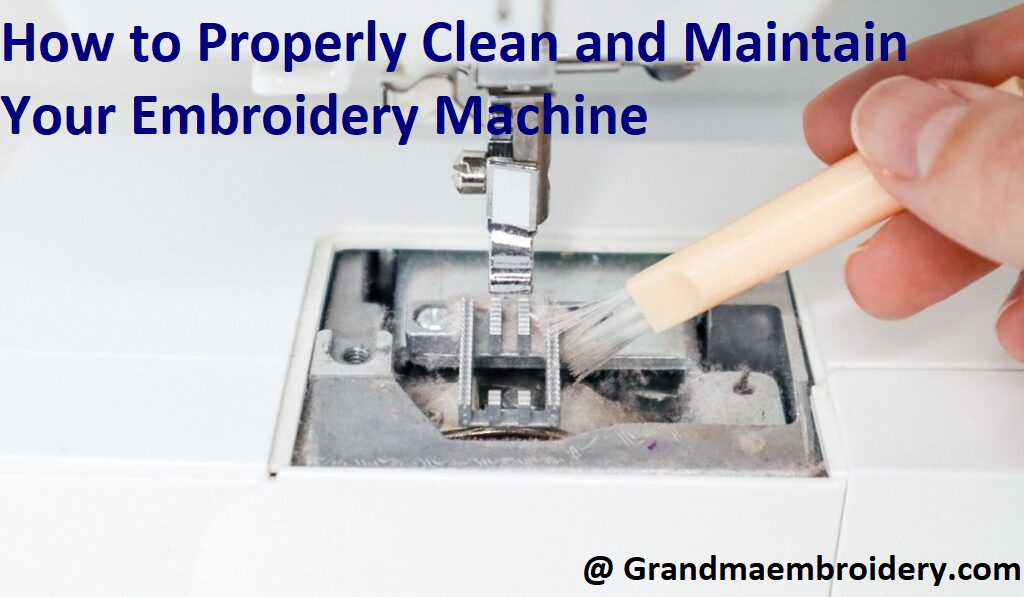

Begin by cleaning the exterior of your embroidery machine. Use a soft lint-free cloth or microfiber cloth to wipe down the surface of the machine, removing any dust or dirt that may have accumulated. Use a soft-bristled brush to clean the hard-to-reach areas such as around the buttons and knobs.

Cleaning the Interior of the Machine

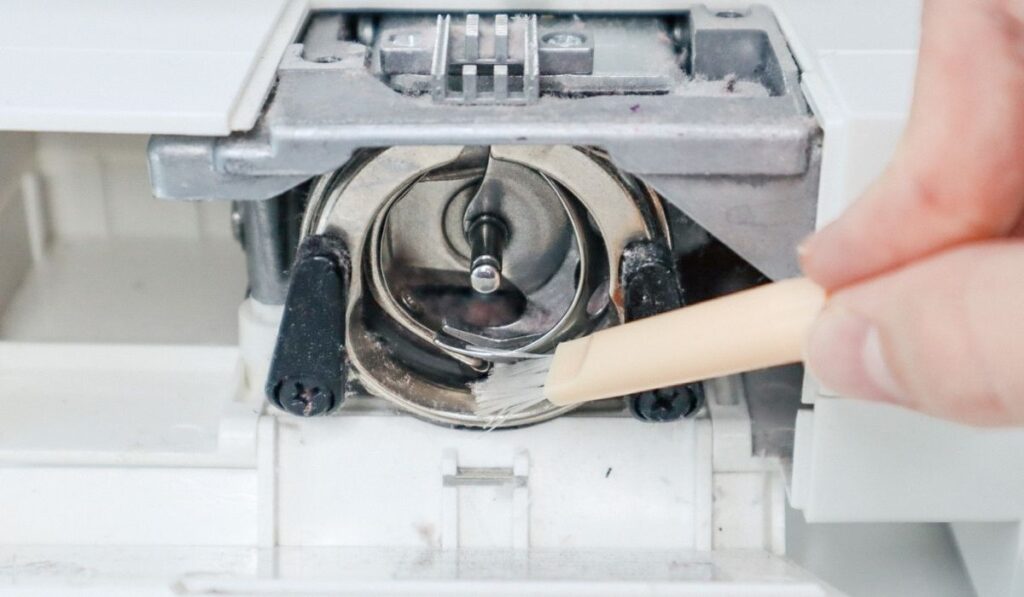

To clean the interior of the machine, start by unplugging it from the power source. Next, remove the embroidery hoop and any other attachments or accessories from the machine. Use a soft-bristled brush to remove any dust or lint that may have accumulated inside the machine. Be gentle and avoid using too much force.

Once you’ve removed as much dust and lint as possible, use a small amount of isopropyl alcohol and a lint-free cloth to clean the feed dogs, bobbin case, and other metal parts inside the machine. Be careful not to get any alcohol on the plastic parts or the embroidery unit.

Lubricating the Machine

After cleaning the machine, it’s important to lubricate it properly. Follow the instructions in your machine’s manual to determine the appropriate areas to lubricate and the type of oil to use. Use only high-quality sewing machine oil and apply it sparingly to the recommended areas.

By following these steps regularly, you can ensure that your embroidery machine stays in excellent condition and produces high-quality embroidery designs.

III. Maintaining your Embroidery Machine

In addition to regular cleaning, proper maintenance of your embroidery machine is crucial for ensuring its optimal performance and longevity. Here are some key maintenance tasks you should perform on your embroidery machine:

Regularly Checking and Replacing Needles

Embroidery machine needles can dull or become damaged over time, which can affect the quality of your embroidery designs. It’s important to check the needles regularly and replace them as needed. Experts recommend changing needles after every 8-10 hours of use or after every project.

Proper Thread Use and Tension

Using the right thread type and tension is crucial for producing high-quality embroidery designs. Make sure to use high-quality embroidery thread that is compatible with your machine. Also, ensure that the thread tension is properly adjusted for each project.

Checking and Adjusting Bobbin Tension

The bobbin tension also affects the quality of embroidery designs. It’s important to check the bobbin tension regularly and adjust it as needed. Follow the instructions in your machine’s manual to determine the correct bobbin tension setting.

Updating Software and Firmware

Embroidery machine manufacturers often release software and firmware updates that can improve the machine’s performance and fix any bugs or issues. It’s important to regularly check for updates and install them as needed. This will ensure that your machine is up-to-date and functioning optimally.

By performing these maintenance tasks regularly, you can keep your embroidery machine in excellent condition and produce high-quality embroidery designs for years to come.

Tips for Long-Term Maintenance

Proper maintenance is key to keeping your embroidery machine in good working order for the long term. Here are some additional tips for maintaining your machine over time:

Proper Storage of the Machine

When not in use, it’s important to store your embroidery machine properly. Keep it covered with a dust cover or cloth to protect it from dust, dirt, and other contaminants. Store it in a dry, cool, and well-ventilated area, away from direct sunlight and heat sources.

Cleaning After Every Use

Cleaning your embroidery machine after every use can help prevent the buildup of dust, dirt, and lint that can cause problems over time. Take the time to wipe down the machine with a soft cloth and use a soft-bristled brush to clean out any dust or lint that may have accumulated. Pay attention to hard-to-reach areas and use isopropyl alcohol for stubborn stains or buildup.

Routine Maintenance Schedule

Create a routine maintenance schedule to keep your embroidery machine in optimal condition. This should include regular cleaning, needle replacement, thread tension checks, and bobbin tension checks, as well as any software or firmware updates. Refer to your machine’s manual or consult a professional technician for guidance on the appropriate maintenance schedule.

By following these tips for long-term maintenance, you can ensure that your embroidery machine stays in excellent condition and continues to produce high-quality embroidery designs for many years to come.

Troubleshooting Common Issues

Even with proper cleaning and maintenance, embroidery machines can experience common issues that can affect the quality of your embroidery designs. Here are some tips for troubleshooting some of the most common issues:

Thread Breakage

Thread breakage is a common issue that can occur due to various reasons such as incorrect tension, worn or damaged needles, improper thread use, or threading the machine incorrectly. To troubleshoot thread breakage, try the following:

Check that the machine is threaded correctly and that the needle is properly installed.

Ensure that the thread tension is properly adjusted for the type of fabric and thread you’re using.

Check the needle for wear or damage and replace it if necessary.

Ensure that the thread spool is properly placed and that the thread is feeding smoothly.

Tension Issues

Tension issues can cause various problems with your embroidery designs such as loops, puckering, or uneven stitches. To troubleshoot tension issues, try the following:

Check that the machine is threaded correctly and that the needle is properly installed.

Ensure that the thread tension is properly adjusted for the type of fabric and thread you’re using.

Check the bobbin tension and adjust it if necessary.

Try using a different type of thread or needle to see if that resolves the tension issue.

Skipping Stitches

Skipping stitches can occur when the needle doesn’t pick up the bobbin thread properly, causing gaps in the embroidery design. To troubleshoot skipping stitches, try the following:

Check that the machine is threaded correctly and that the needle is properly installed.

Ensure that the needle is not bent or damaged and that it’s the correct size and type for the fabric you’re using.

Check the needle bar for any burrs or damage that may be affecting the needle’s movement.

Try using a different type of needle or thread to see if that resolves the skipping stitches.

Needle Breakage

Needle breakage can occur due to various reasons such as using the wrong type or size of needle, using dull or damaged needles, or using incorrect tension. To troubleshoot needle breakage, try the following:

Check that the needle is the correct size and type for the fabric you’re using.

Ensure that the needle is not dull or damaged and replace it if necessary.

Check the needle bar for any burrs or damage that may be affecting the needle’s movement.

Check the thread tension and adjust it if necessary.

By following these troubleshooting tips, you can identify and resolve common issues with your embroidery machine and ensure that your designs are of the highest quality. If the problem persists, consult your machine’s manual or a professional technician for further assistance.

Conclusion

Proper maintenance is crucial for ensuring the longevity and performance of your embroidery machine. By regularly cleaning, checking and adjusting tension, and updating software and firmware, you can keep your machine in optimal condition and avoid common issues that can affect the quality of your embroidery designs.

A well-maintained embroidery machine not only produces high-quality designs but also reduces the risk of costly repairs or replacement. Additionally, a properly maintained machine will save you time and frustration in the long run, allowing you to focus on your creativity and productivity.

In conclusion, remember to keep your machine clean and well-maintained, follow a routine maintenance schedule, troubleshoot common issues promptly, and store it properly when not in use. By following these tips, you can ensure that your embroidery machine remains in excellent condition and continues to produce beautiful designs for many years to come.

See Also-

- Best Janome Embroidery Machine 2023

- Best Embroidery Machine For Clothing 2023

- Best Commercial Embroidery Machine 2023

- Best Embroidery Machine For Patches 2023

- Best Affordable Embroidery Machine 2023